How-to Article ...by Gregg Kiehle of Voodoo Props LLC

Give your prop a little "Voodoo" with tips and tricks from Gregg Kiehle of Voodoo Props LLC!

The following are the step by step instructions I use for balancing and polishing my VooDoo 17-4 PH hardened stainless-steel propellers.

Clear out any burrs that might be trapped inside the hub of the propellers. I use a .001 over-spiral reamer to insure a nice fit on the boat shaft. I do this first, because if you wait until the end, the prop will be very sharp. Doing it now will lessen your chance of injury, if the prop catches the on the drill. I also wear leather gloves, because even a dull spinning prop can cut you very badly… I experienced that too many times!

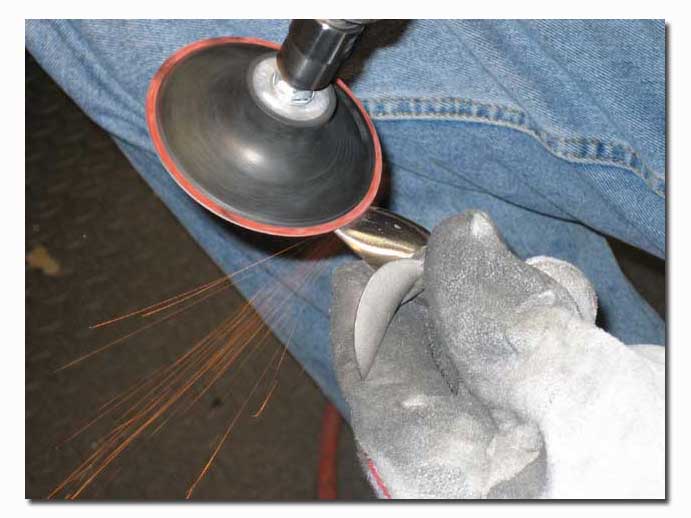

I start with my angle die grinder, and work with a Standard Abrasive 120 grit soft lip 2-inch disc, working out any imperfections that might be on the face of the blade. With the soft edge, you can easily work the blade face and contour all the way up and into the valley, where the blade meets the hub. Be careful not to disturb the trailing edge of the blade. Now move onto a 2-inch soft wheel and scotch bright.

That will remove any deep scratches and smooth out any sanding marks. (change the direction you sand in order to leave a cross-hatched sanding pattern). This will make it easier to buff out later.

I then move to a 3M synthetic 320 grit 6-inch yellow bristle brush on the end of my grinding-wheel arbor, and go over it, working across the blade face until I have a smooth satin finish. Now I move to the final polish of the front of the blade. Yes, you read it right. I do the final polish of the blade face at this point because you will never have to touch this surface again. You can get a more even finish across the back of your blades if you get this step out of the way. I start polishing, working from the leading edge of the drive dog end, and work across the blade face until a mirror polish is obtained. This is done using Black Magic buffing compound. That part being done, I move on to the back of the blade. This is by far the easiest part to work on.

I start with a 3 inch soft lip 120 grit Standard Abrasive disc, on my angle die grinder. Working it in a back and forth movement, across the back of the blade, concentrating from the trailing edge down to about 3/16ths from the leading edge, thinning a lot out of the valley were the hub meets the blade. This is the thickest spot and can be thinned the most. Staying away from the leading edge at this point, you lessen the risk of over thinning it. This is very easily done, and when you go to polish it, you can remove too much of the blade area.

With the stainless propellers, you are able to go much thinner than before. For instance, on a 376 Nibil Bronze 6717-3, the blades start to yield every lap with a prop that weighs 24 grams or less. The same prop in 17-4 PH can be thinned to less than 18 grams total weight, with zero blade yield. Now, when the propeller blade is roughed, it is time to get down to business. Any blade shaping or profiling should be done at this point. I do not recommend drastic modifications on the bronze propellers. They will throw blades and cannot withstand the stresses that the new motors are putting on them.

OK, after your blades are shaped to your liking, we go to the thinning process. This is the same as above, but now we are working to get the blade relatively the same thickness through out the entire surface.

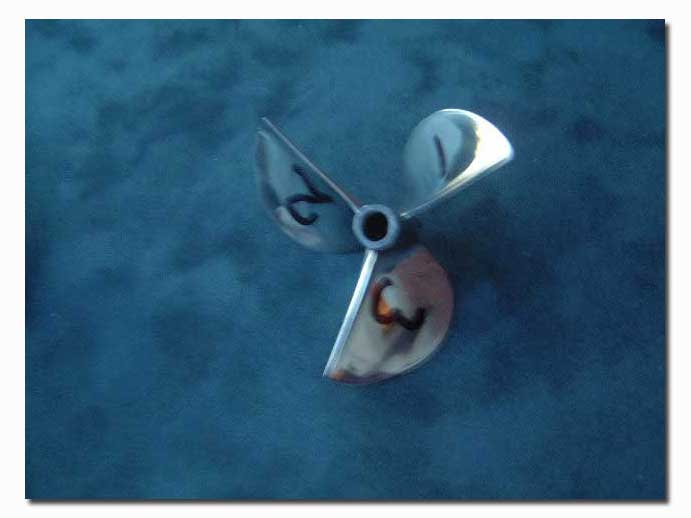

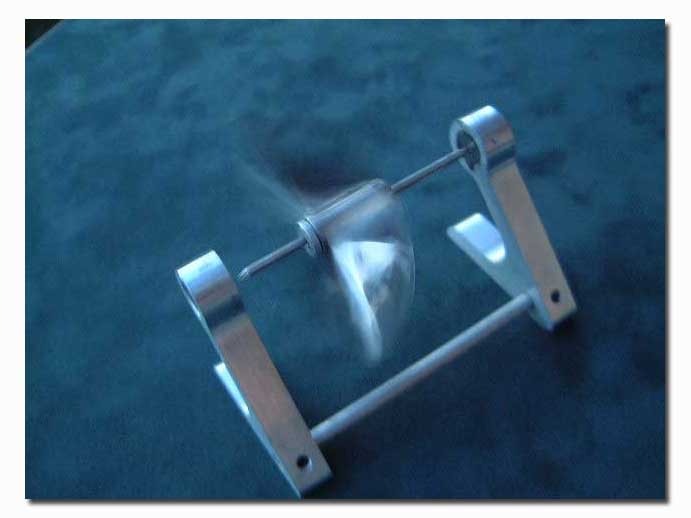

Moving on to the final steps of balancing and final polishing: I start by numbering the blades 1, 2, 3 with a Sharpe marker. This makes it easier to balance the prop and determine which blades are heaviest. I start out spinning it on my Zero G balancer. When it stops spinning, the heaviest blade will drop to the bottom.

A little secret: if both blades hang parallel to the ground, most likely they are both heavy. I remove material from the back of the blade, using my 1" X 42" Burr King belt sander, with a Trizac A 16 belt. These belts are coated with pyramid grit that sands as smooth as silk. They do not cause deep gouges from loose grit. You can go right to final polish from this step once you have balanced all three blades. You will know the prop is properly balanced when you spin the prop and it never stops in the same position twice. The blades should all hang in a different position every time you spin the prop on the balancer. The back should be smooth and consistently finished. You are then ready to move on to the final polish.

I use a screwdriver with a ¼ inch shaft on it (with the head cut off), to hold my prop. I strongly recommend the use of a leather apron and face shield because if one of these little beauties comes off the wheel, you will not be able to get away fast enough. Trust me on this. Also, I have learned, from experience, that once you start polishing, work the back of the blade from the trailing edge to the leading edge. Always trying to go cross the grain of the sanding marks from hub out to tip. Be careful, the leading edge will buff away the fastest along the tips. If you buff off a tip, don't panic, you can make all blades the same and consider it a prop with reduced lift. I polish these with a bar of Black Magic polishing compound. It has good cutting with excellent color or final finish. After all these steps have been taken, you will truly have a prop that will be the envy of all. Remember always wear safety protection on your hands, body and face. By following these simple steps you can try prepping some of your own propellers, save some money and have a much larger prop selection.

Voodoo Props LLC is a manufacturer of propellers for gas, nitro and electric powered model boats. They specialize in 376 Bronze and 17-4 ph Stainless Steel propellers. Propellers are available in 3 different finishes: Raw, Polished only or Polished-Balanced-Sharpened.

For More information:

Voodoo Props LLC Gregg Kiehle Phone: 586-707-4734 Email: This email address is being protected from spambots. You need JavaScript enabled to view it. Website: www.voodooprops.com