Product Review Article...

Part 2...Follow-up article on the J&G Hemi kit for Zenoah engines...

.jpg)

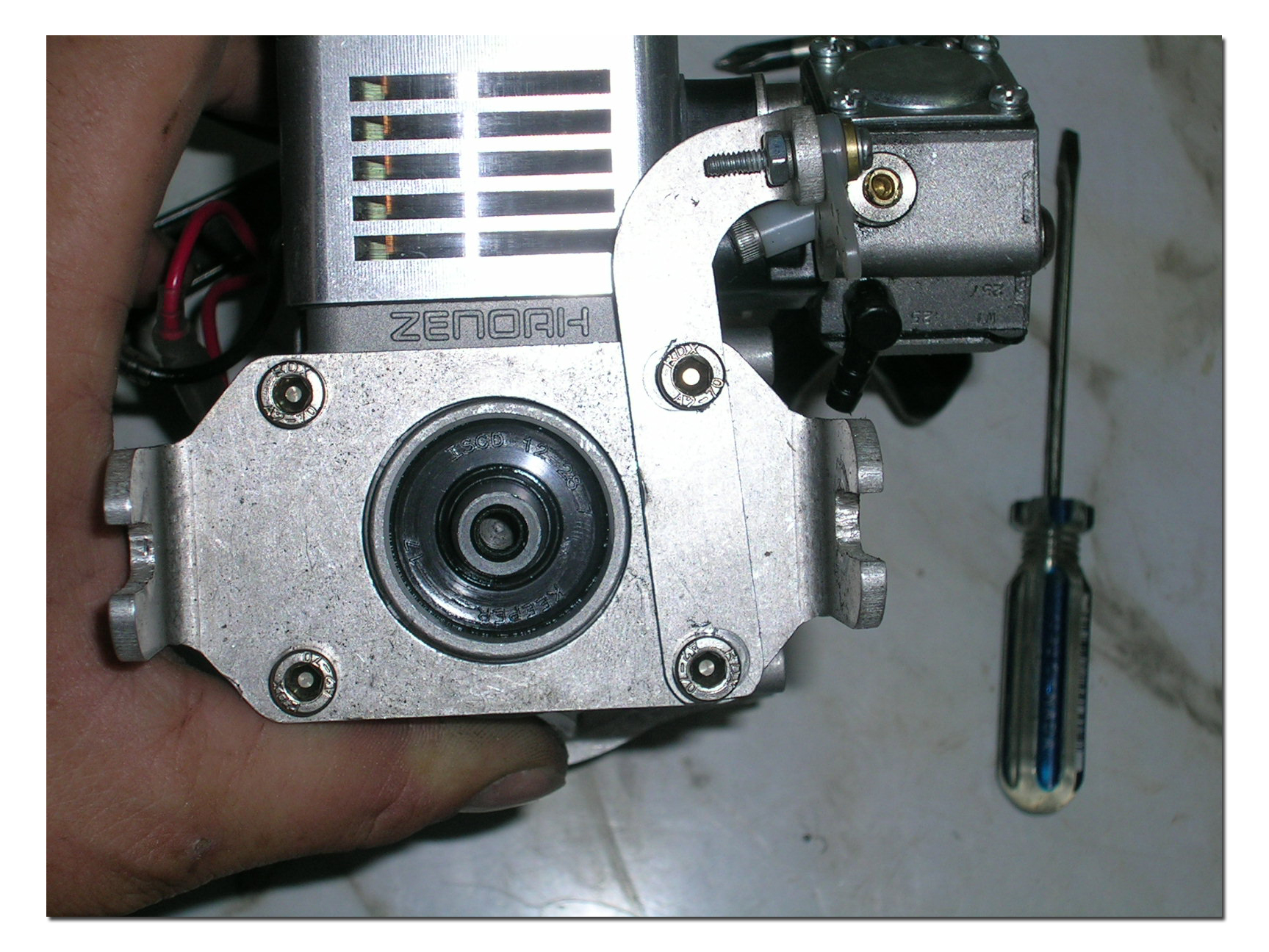

Back in Issue 14 we did an article on the J&G performance top end kit for Zenoah engines. At the time the motor had not been tested and the article was more of a "how-to" assemble article. Since then I have had the time to run the motor and in this short article I want to report my findings.

The first thing I noticed when came the time to install the motor into one of my boats was that the throttle linkage I was using did not match up to the carburetor correctly. I typically use Insane/CC Racing mounts, which have a direct bellcrank throttle linkage setup. The fact that the J&G cylinder's overall width is less than the original Zenoah cylinder placed the carburetor closer to the motor's centerline. I had to slot the mounting holes in the bellcrank bracket to allow me to tilt it in a little bit. This was an easy modification to make, and still allows me to use the linkage on a Zenoah motor by simply sliding it back to its original position.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

The first thing I did with the motor was set it up on my test bench and broke it in by running about 40 oz of gas through it. I ran it at varying throttle settings and monitored head temperature. The motor was spinning a large airplane propeller on the test bench to ensure it had a constant load. It was continuously supplied with cooling water via a small pump in the setup.

The engine ran great and showed much potential. The throttle response was excellent (using a modified Walbro 257 carburetor and a 2" band pipe) and the RPM were impressive. I did notice however that the motor seemed to run a little bit hotter than your typical modified Zenoah 260.

After the test runs, I opened up the motor to make sure everything looked ok...it did.

So I mounted the motor in my hydro and headed to the lake. I ran the boat for about an hour or so, on and off, trying different propellers and settings. Running the motor in a boat is where I really began noticing how hot it really did run. It had me concerned, so I double checked everything to ensure that I had proper water flow. Everything was fine. The motor showed promise during these first test runs, but I was a little bit disappointed. For some reason I was expecting more out of it, but the fact is that it performed about even with a modified 260. I then realized that I should not be discontent, in fact it was quite acceptable performance considering that this kit was a direct bolt-on accessory that actually yielded performance similar (in many cases superior) to many of the modified 260s out there!

I took the motor back to the shop and opened it again to inspect it. I was worried that the hot running conditions could have damaged the motor. Again everything looked fine though.

Some time went by before I got to run the J&G motor again, and during that time I had some discussions with Carlo Catalanotto of CC Racing Engines concerning my testing. Carlo suggested that I cut down the top of the piston as we typically do with the Zenoah 260s. I must say that even with the stock piston I ran for the first tests I did not notice any premature wearing of parts, maybe due to the slow break-in, but Carlo suggested I cut it anyway to be safe. He also told me of some modifications that I could do to the motor. So I got to work. I installed a cut down piston that I had in my parts. It is a custom piston from Needforspeed Hobbies that features a ceramic coated top and Teflon coated sides. The top is also cut down. The piston is also lightened. I also modified the flywheel and did some fine detail work inside the motor. Now I don't want to get into too many details here though...I suggest you get your motor to Carlo if you want to have mods done to it.

I ran the engine on the test bench again and immediately there was a noticeable increase in performance. I then installed the motor in the new Aeromarine XXX OUterlimits hull that I reviewed in this issue. At the lake the performance increase was even more noticeable, especially in this high performance mono. The first time out the motor still seemed to run hot, but after correcting some cooling issues in the setup it was much better. I was now also using a prototype 0 band steel pipe from Needforspeed Hobbies. This is what you would consider more of an RPM pipe as opposed to a 2" band pipe. I figured this would better match the purpose of the J&G motor and it worked quite well.

Now the thing to keep in mind with the J&G Kit motor is that it is a high revving motor so you have to use smaller props than you would typically use with a Zenoah in most cases. This is where I was going wrong in my first on water testing attempts with the hydro. I was trying to push the same props I usually do when using my Zenoah motors and was loading the motor up too much. Use smaller diameter propellers and let the engine run at high RPM and it will perform great and pull strong through the turns and in the straights. You have to do some testing to find what performs best with your setup, but that is part of the game!

A side note about maintenance for the J&G Kit motor. I would strongly recommend you flush out the water jacket with.jpg) WD40 or similar after a day at the lake. Otherwise, the top section of the sleeve will rust if water is left inside the motor. I experienced this and had to take the motor apart to clean up the mess. This is actually a good habit to take with all motors, but it is especially important in this case.

WD40 or similar after a day at the lake. Otherwise, the top section of the sleeve will rust if water is left inside the motor. I experienced this and had to take the motor apart to clean up the mess. This is actually a good habit to take with all motors, but it is especially important in this case.

Final comments...

Although I have no very long term testing done, I really like the J&G V2 Hemi Kit motor. It is an easy to assemble kit that will put your stock Zenoah 260 up there with its modified competitors. With a little extra modifying, it will be even stronger. Be certain to use a NEW Zenoah motor as the donor and ideally have the top of the piston turned down as would be done for a modified Zenoah. Follow the fuel mixture recommendations from the manufacturer and a good carburetor (Walbro 257 recommended). You also want to ensure that the motor gets proper cooling at all times.

Remember that this motor likes to rev so prop accordingly and have a blast!

Happy Boating!