Tech Article... by Xavier Cardinale

An interesting article on how to check and realign crankshafts.

How to balance a bad crankshaft ?

Why balance a crankshaft ?

Those are the questions that may have remained unanswered for you.

Let's take a moment to talk about crankshafts and how to use them in an optimum manner.

Crankshaft

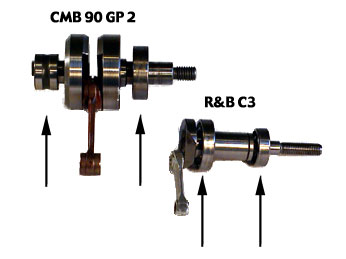

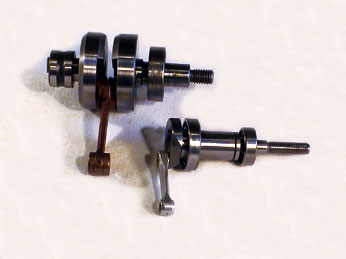

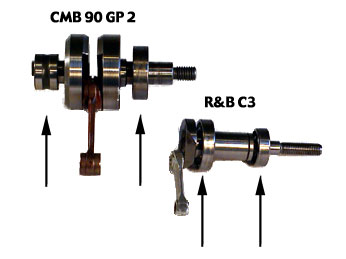

Two crankshaft types :

On the left, the arrows point out the ball bearing points.

On the left, the arrows point out the ball bearing points.

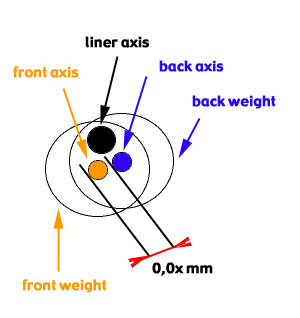

On the R&B C3 engine, the crankshaft works in a bad mode which cause a much higher wear and tear of the ball bearing.

On CMB 90GP2, the equally distributed forces on both sides of the liner explain the much lesser wear and tear.

Our expertise has shown that a regular check on two hour basis (equal two races) and at each crash makes sense.

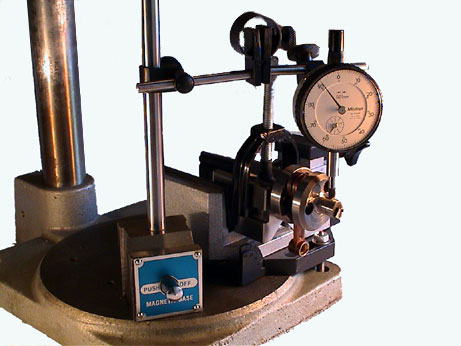

Crankshaft Tool

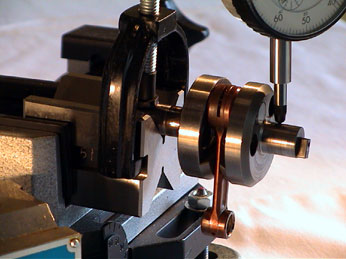

This self-made tool fits the needs of most CMB engine users.

This way it is possible to adjust axis with real good precision (1/100mm).

The measurement is done on the axis and not on the weights.

It was This email address is being protected from spambots. You need JavaScript enabled to view it., know as French CMB reseller,

who showed us this equilibration tool and how to use it.

The customizing has been done by This email address is being protected from spambots. You need JavaScript enabled to view it..

On the left picture, we can see how the crankshaft is fixed

between a metal V-shaped piece and a blocking screw.

On the right picture, we can see how the mesure is taken

using a high precision tool.

To measure the right equilibration of the crankshaft, we use

the high precision tool whith the head point under a certain pressure

onto the crankshaft axis.

Then we have to turn the axis to evaluate the axis behavior.

The acceptable variation should not exceed 0.02 mm (according Alain Blayer).

How to adjust the crankshaft

This second step will consist in correct adjustment of the two crankshaft weights.

Therefor we mainly need three tools : hammer, screw driver and spanner.

• First use the hammer to move the crankshaft weight. Don't hesitate to hit strongly but don't destroy it.

Proceed as shown on upper pictures. To maintain the crankshaft free, we need a wooden support piece as designed by Francis Cardinale.

Repeat the operation several times.

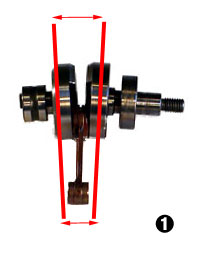

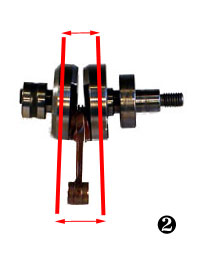

• Second control the parallelism of the crankshaft weights

On pictures (1) and (2) the parallelism are excessively drawn !

(1) In this case we have to join the weights. With the spanner...

(2) In this case we have to separate them. With the screw driver...(like picture to the left)

Be careful this action should be done with precision and in small steps (1/100 mm !)