Product Review Article ...

A look at the Cajun Bullet outrigger hydro...

Outrigger hydros are known as the top speedsters on the water. With today's highly modified gasoline motors, they can routinely run at speeds in excess of 70 mph and much more. The Cajun Bullet Gas Hydro, built by Harold Broussard, continues to support the notion that gasoline powered boats are capable of extreme speeds and performance.

After a couple of racing seasons with my Evolution Rigger, I was forced to retire the boat due to several unexpected interactions with other immobile floating objects on the race course. But Butch Fields (Butch the Boat Man) came to the rescue and generously allowed me to finish the build out and drive one of his riggers, a Cajun Bullet.

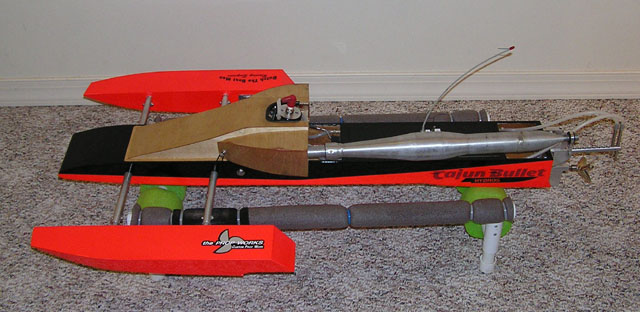

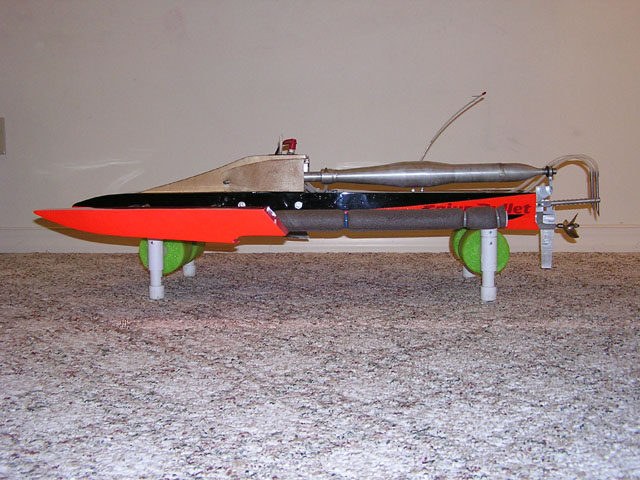

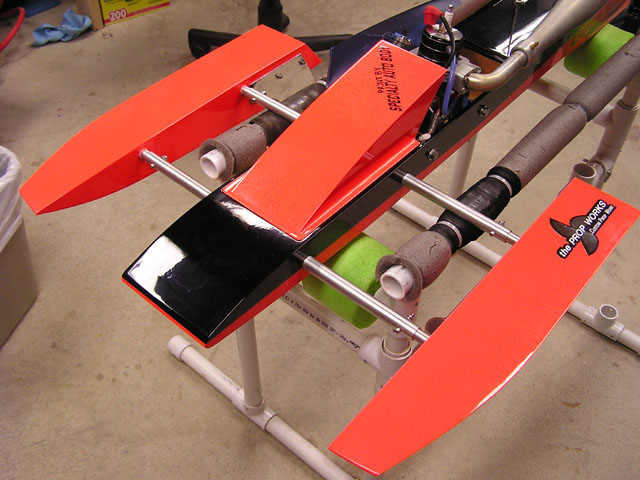

The Cajun Bullet is a large boat. It is 41" long without the transom hardware and 24" wide. The front  sponsons are nearly half the length of the boat at 20", though the actual water line is smaller since the sponsons have a deep step cut at the back.

sponsons are nearly half the length of the boat at 20", though the actual water line is smaller since the sponsons have a deep step cut at the back.

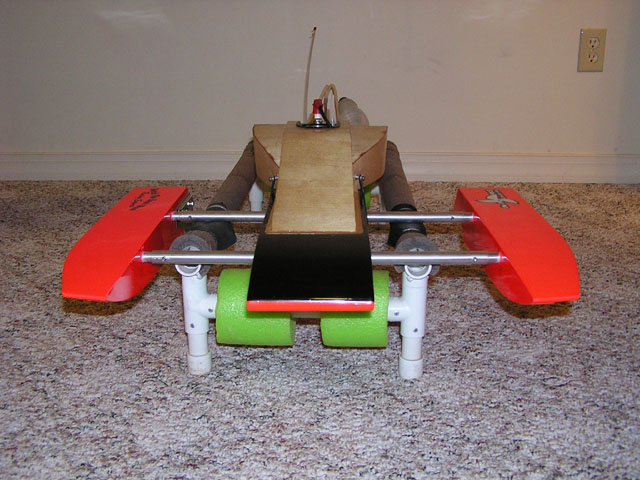

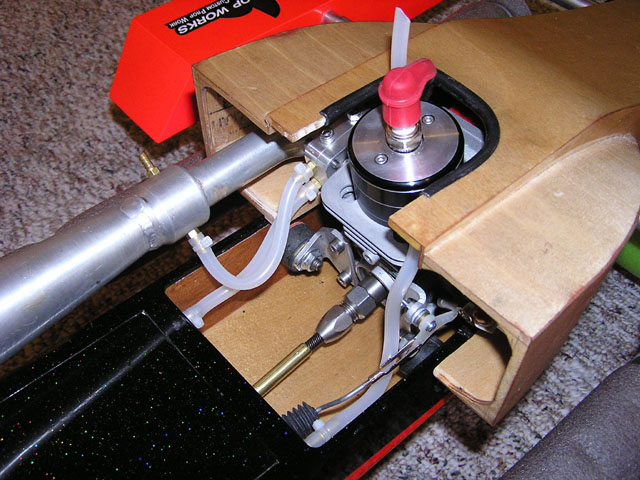

The boat is built very solid with excellent wood work all around. There is a full height "firewall" wood piece between the motor and the fuel tank section of the boat which helps stiffen this area, but it requires drilling to allow for the passage of the fuel lines. The hull is perfectly straight and true; the radio box lid fits perfectly as well as the cowling. The epoxy sealing on the boat was a little rough and needed some sanding to smooth it prior to painting, though.

The boat is built very solid with excellent wood work all around. There is a full height "firewall" wood piece between the motor and the fuel tank section of the boat which helps stiffen this area, but it requires drilling to allow for the passage of the fuel lines. The hull is perfectly straight and true; the radio box lid fits perfectly as well as the cowling. The epoxy sealing on the boat was a little rough and needed some sanding to smooth it prior to painting, though.

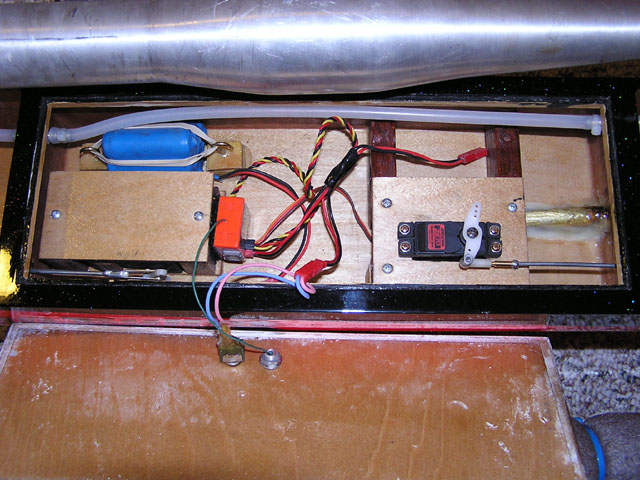

The radio box is designed as single section of the boat which is very large and provides ample room for large receivers and battery packs, but this section of the boat has a tendency to "torque-flex" a little and I'm tempted to epoxy a wooden support piece in the middle to make it a little more rigid. The boat comes with servo mounts built in, accepting a standard Futaba 1/4 scale steering servo and Futaba throttle servo (both servos included). The servo mounts were set up for having the rudder on the right side, and the throttle servo on the left side. If you prefer the rudder and throttle on the opposite sides, let Harold know when you order the boat to have the mounting points moved. I prefer the rudder on the left side, but the boat came to me with the rudder already drilled so I left it in place on the right. I did move the steering servo to the right so I can use the Hyppertorque throttle bell crank.

large receivers and battery packs, but this section of the boat has a tendency to "torque-flex" a little and I'm tempted to epoxy a wooden support piece in the middle to make it a little more rigid. The boat comes with servo mounts built in, accepting a standard Futaba 1/4 scale steering servo and Futaba throttle servo (both servos included). The servo mounts were set up for having the rudder on the right side, and the throttle servo on the left side. If you prefer the rudder and throttle on the opposite sides, let Harold know when you order the boat to have the mounting points moved. I prefer the rudder on the left side, but the boat came to me with the rudder already drilled so I left it in place on the right. I did move the steering servo to the right so I can use the Hyppertorque throttle bell crank.

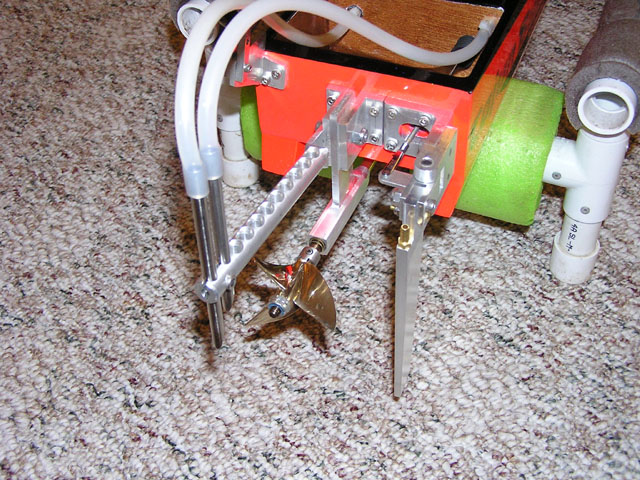

A single brass water tube is pre-installed to run through the radio box. Since I decided to go with dual prop wash water pickups, I added an extra water line to the other side of the radio box.

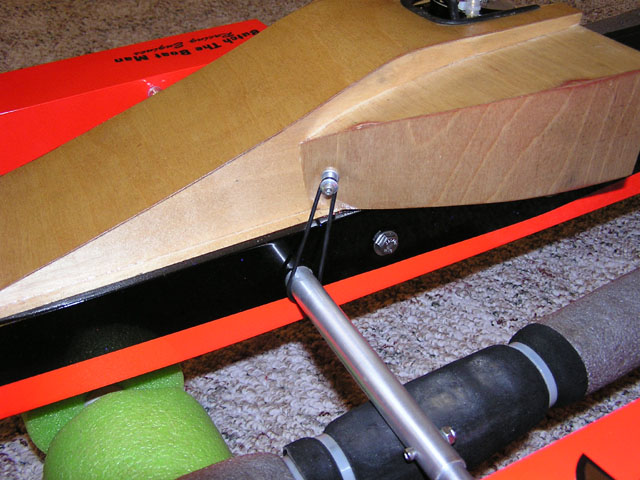

I think the long front sponsons add to the overall stability of the boat in addition to providing a very solid mounting surface for the turn fin. Since the sponsons go as far back as the CG of the boat, the turn fin does not need an extension or a bracket. It can be mounted directly to the side of the sponson. The turn fin mount points are prebuilt into the right sponson; created by embedding solid aluminum rods that are drilled and tapped for 6-32 bolts.

I think the long front sponsons add to the overall stability of the boat in addition to providing a very solid mounting surface for the turn fin. Since the sponsons go as far back as the CG of the boat, the turn fin does not need an extension or a bracket. It can be mounted directly to the side of the sponson. The turn fin mount points are prebuilt into the right sponson; created by embedding solid aluminum rods that are drilled and tapped for 6-32 bolts.

The mounting rods are encased in a wood dowel prior to being epoxied in place. This works very well as it does not rely solely on the wood siding to hold the turn fin. I added a strip of 1/8" aluminum over the turn fin to provide more compression surface area for the smallish 6-32 bolts.

The boom tubes are made from aluminum and are pre-drilled so the front sponsons are at fixed widths from the tub. The left sponson is set at 6-1/4" while the right sponson is set at 5-3/4". Having the extra offset on the left can make the boat more stable through the turns during heat racing. The sponsons also have a ride pad on the bottom which reduces the surface area on the water when the boat is at full speed.

The boat also has rear sponsons that run directly under the tub. They help keep the back end off the water through the turns and eliminate any hopping through the straights.

A recent improvement to the gas Cajun Bullet Hydro is the full size cowl with the integrated carburetor cover (the cowl in the pictures has not been painted yet). The old cowl was a relatively simple cover that sloped up from the fuel tank area to the front of the motor. The new cowl is more complex with symmetrical covers extending over the carb and over the exhaust header. It works very effectively as a carb cover prevent the ingestion of water spray, and the large angled surface adds down force when the boat is rocketing across the pond.

Although I'm still in the process of fine tuning the boat, I'm able to do very tight full speed ovals at 70 mph powered by Butch Field's high performance racing motor and Bob Austin's props. The boat ran well with Prop Shop 6719/3, 6717/3, and 6518/3 props.

The Cajun Bullet Hydro is a very stable boat. It is capable of running extremely fast and handling all the chop you can throw at it. The extra length, width and to some extent, the weight (without fuel the boat weighs in at just over 12 lbs.) make this boat an excellent heat racing boat. Winning a race is more often than not, more about finishing a race, and I suspect that we'll see many more 1st place trophies taken home by Cajun Bullet owners!

Harold Broussard, 71, builds Cajun Bullet Outrigger hydros full time and he's been building model boats for 27 years. He retired after working in a shipyard for 43 years building and racing full size wood boats. Although he builds nitro riggers, he's been noticing a very significant increase in the demand for his gas powered model.

The boat comes completely sealed with System3 Epoxy. The stuffing tube, strut, rudder, and motor mount are all installed and included. The radio box has the servo mounts in place and both the steering and throttle servos are included. The turn fin mounts are in place but you will still need to drill the holes in the turn fin, allowing to make adjustments for CG if necessary (the turn fin has a line scored in it so you know where to drill the holes). The new cowling is included and it is fully sealed as well. Basically all you have to supply is the motor, tuned pipe , receiver, prop shaft/flex cable, prop and fuel tank. It generally takes Harold two weeks to build a boat, but it can take longer depending on his backlog. Contact Harold for the current pricing on the boat.

Paint by Dean Werges of Specialty Auto Body.

Contact Information:

Harold Broussard

Web: www.cajunbullethydros.com